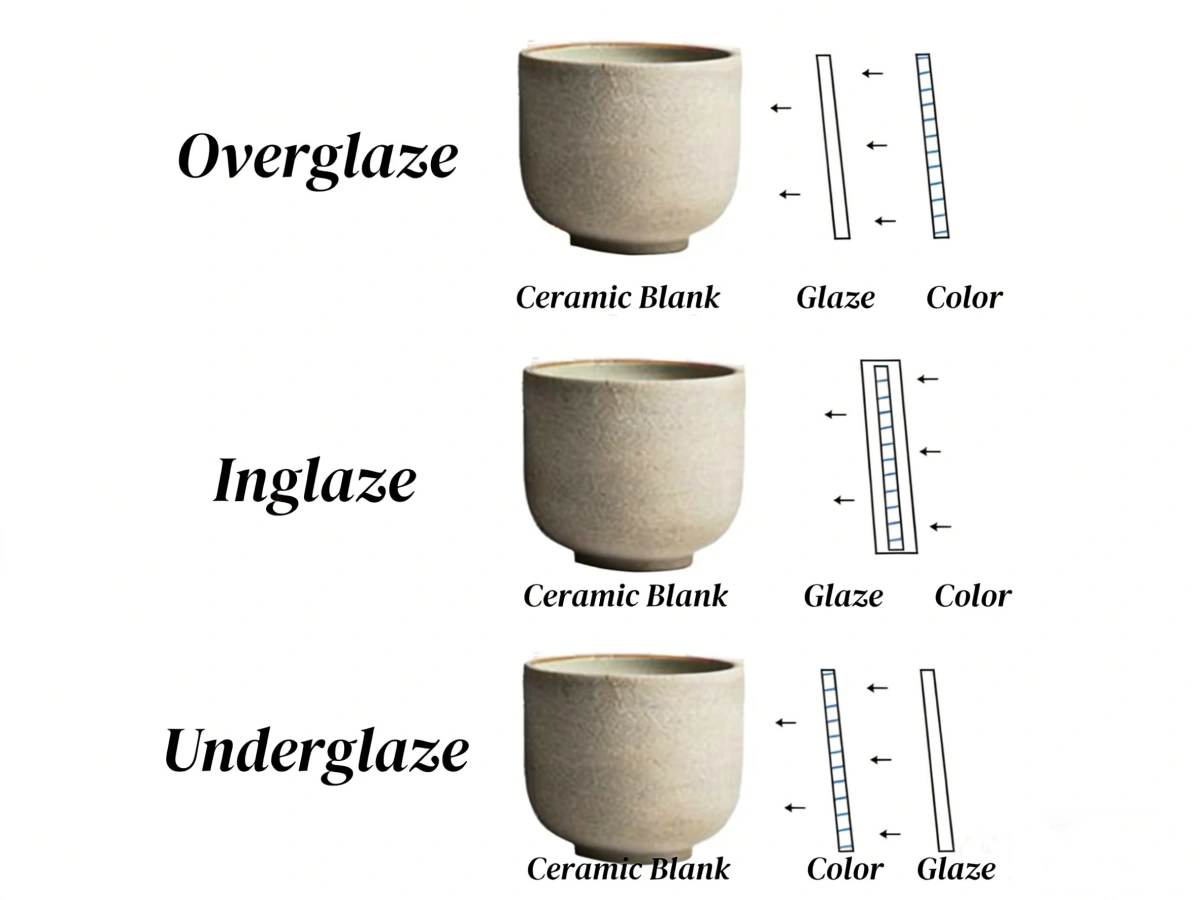

Explore ceramic decorating techniques — an in-depth comparison of overglaze, in-glaze, and underglaze techniques to help you understand their differences, applications, and advantages and disadvantages.

What is Ceramic Glaze?

Before unveiling the three methods of decoration, it’s pertinent that the term “glaze” be understood. “Glaze” refers to the glass-like layer applied to the surface of ceramics. Its functions include making ceramics water- and wear-resistant, having color, and having glossy effects.

1. Overglaze: Secondary Decorating Technique

Overglaze decoration entails the use of glazing and high temperature firing to stabilize the glaze. Color decoration is then applied to the surface of the glaze and low temperature firing is performed in order to bond the pigments to the surface of the glaze.

Features

- More intricate patterns, incorporating more colors for intricate designs

- Its design is painted on the surface of the glaze, with observable layers

- Generally requires a second low-temperature firing

2. In-glaze: Glaze Layer Fusion Decoration

In-glaze decoration refers to the process of applying colored pigments on the glaze before the final high-temperature firing while the glaze has not yet hardened, hence getting melted together with the pigments, thus achieving the blending of colors.

Features

- More natural fusion of color and glaze

- The pigments tend to peel less easily

- Generally fires at one high temperature.

3. Underglaze: Stable Under-Glaze Decoration

Underglaze decoration entails painting designs onto unfired or low-fired ceramic wares by applying a transparent glaze to cover them and firing them to a high temperature. The design remains sealed underneath a glaze layer to produce a smooth finish with high durability.

Features

- Colorfast and resistant to fading

- The patterns won’t be scratched off by use

- Commonly found in classic decorations such as blue and white porcelain

Comparison of Advantages and Disadvantages of Three Techniques

| Technique | Advantages | Disadvantages |

|---|---|---|

| Aufglasur | Rich color expression; suitable for complex patterns | Requires secondary firing; patterns are on the surface, more susceptible to wear |

| Inglaze | Natural color blending; sturdy and durable | High technical requirements, complex temperature control |

| Unterglasur | Highly wear-resistant, non-fading; single firing | Colors are affected by high temperatures, limited color range |

Why are these techniques important for ceramic products?

Choosing different decoration techniques directly affects the appearance, durability, and usage scenarios of ceramic products. For example:

- If household tableware uses underglaze techniques, the patterns are more durable and safe;

- If gift ceramics use overglaze techniques, they can more richly express details and colors;

- Inglaze is the best choice for achieving deep integration of color and glaze layers.

Authoritative industry sources indicate that underglaze technology is one of the most durable methods of ceramic decoration, as the pigments are sintered under the glaze layer, resulting in a smooth and durable finish. ([Wikipedia])

Qunfa Ceramics: A Globally Trusted Partner in Daily-Use Ceramic Manufacturing

Founded in 1993, Qunfa Keramik specializes in the research and development and manufacturing of household ceramic products, possessing unique OEM/ODM-Fähigkeiten and advanced production equipment. Currently, we have grown into a modern ceramic enterprise covering 30,000 square meters with over 400 employees, and have become a designated supplier for international brands such as Walmart, Costco, Aldi, Disney, C&B, Michaels.

We mainly produce ceramic bakeware and tableware, and have expanded into diversified product lines, including pet supplies and garden planters, meeting the diverse needs of global customers. Welcome global customers to cooperate with Qunfa Keramik to create a bright future for ceramic products!