Expert Ceramics Manufacturing Partner for Daily Use

Excellence in Production, Quality, and Design

Qunfa Ceramics - More Than Ceramics Manufacturing

Production Capacity

Scalability and Efficiency Daily-Use Ceramics Manufacturer

Qunfa Ceramics leverages its strong production capabilities and exquisite technology to provide comprehensive solutions from raw material procurement and manufacturing to final products. As a leading daily-use ceramics manufacturing company since 1993, we have independent control capabilities in several key areas, ensuring efficiency and quality at every stage.

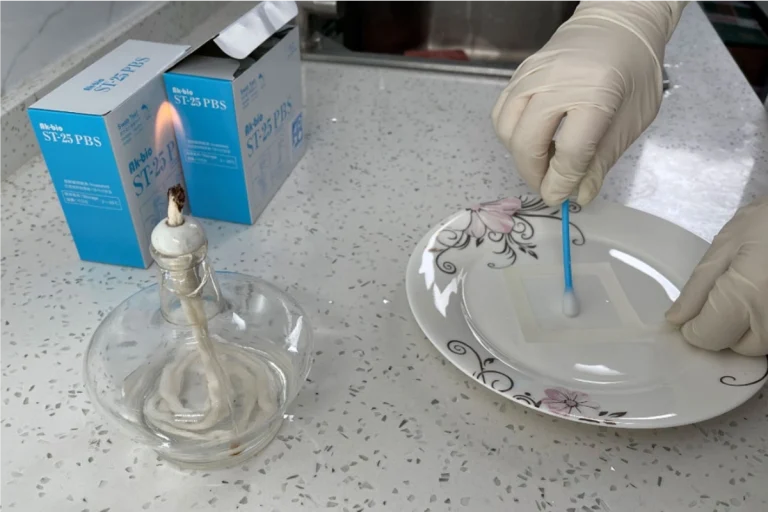

Quality Control

Striving for Excellence, Guaranteeing Quality in Ceramics Manufacturing

Qunfa Ceramics always adheres to the philosophy of “quality first,” strictly following international quality standards to ensure that every product meets food safety, environmental protection requirements, and physical performance indicators. Quality control runs throughout the entire ceramics manufacturing process, from the selection of raw materials to every stage of production, and finally to the final inspection before shipment.

From Production to Perfection: Our Quality Control Process

Raw Material Inspection

All raw materials entering the production line (clay, glaze, etc.) undergo quality inspection. This includes chemical composition analysis, particle size measurement, and moisture content testing to ensure that the raw materials meet standards and prevent quality issues in the final product.

Pre-forming Inspection

Before slip casting, roller forming, or pressing, the accuracy of the molds and the consistency of the raw materials are checked. This includes checking that the mold surface is smooth and undamaged, and that the raw materials conform to the formula proportions, ensuring that the shape and quality of the products meet standards.

Firing Process Monitoring

Before firing, the ceramic blanks are inspected for deformation, cracking, and other problems to ensure product stability after firing. During the firing process, parameters such as kiln temperature, firing time, and cooling rate are monitored. This ensures that the temperature is controlled within the appropriate range, avoiding over-firing or under-firing.

Surface and Glaze Inspection

After firing, the finished products undergo surface quality inspection, including checking for glaze uniformity, color differences, cracks, bubbles, and other defects. This ensures that each finished product has a smooth, flawless surface, uniform color, and no unacceptable glaze problems.

Physical Performance Testing

The finished products undergo testing for physical properties such as hardness, compressive strength, and toughness. This ensures that the products have sufficient durability during use and meet the quality standards for daily-use ceramics.

Final Inspection Before Shipment

Before shipment, all finished products undergo a final inspection. This mainly includes dimensional accuracy, appearance defects (such as cracks, color differences, glaze defects, etc.), and packaging integrity. This ensures that the products meet customer requirements, the packaging is intact and undamaged, and meets transportation standards.

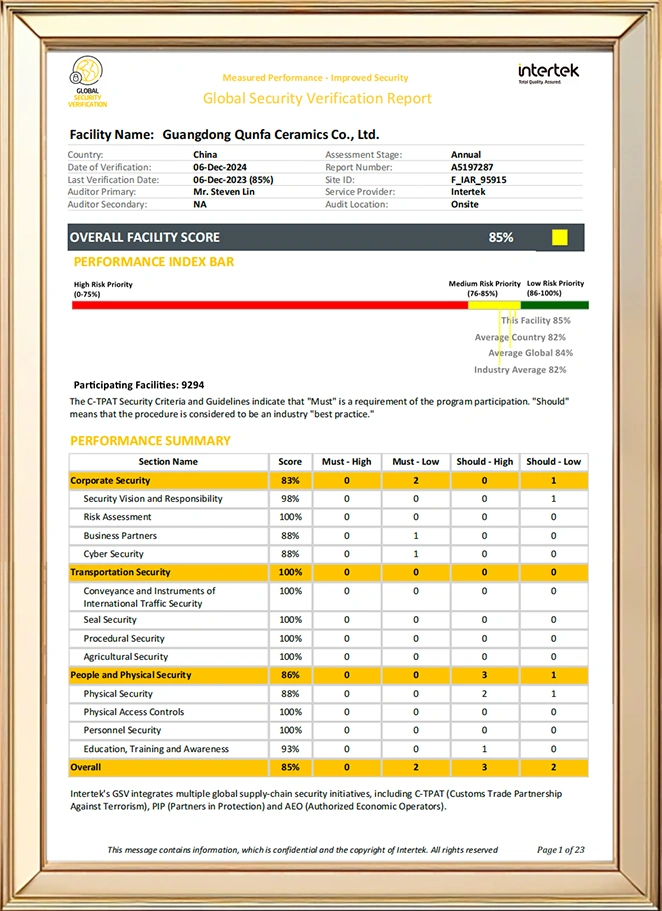

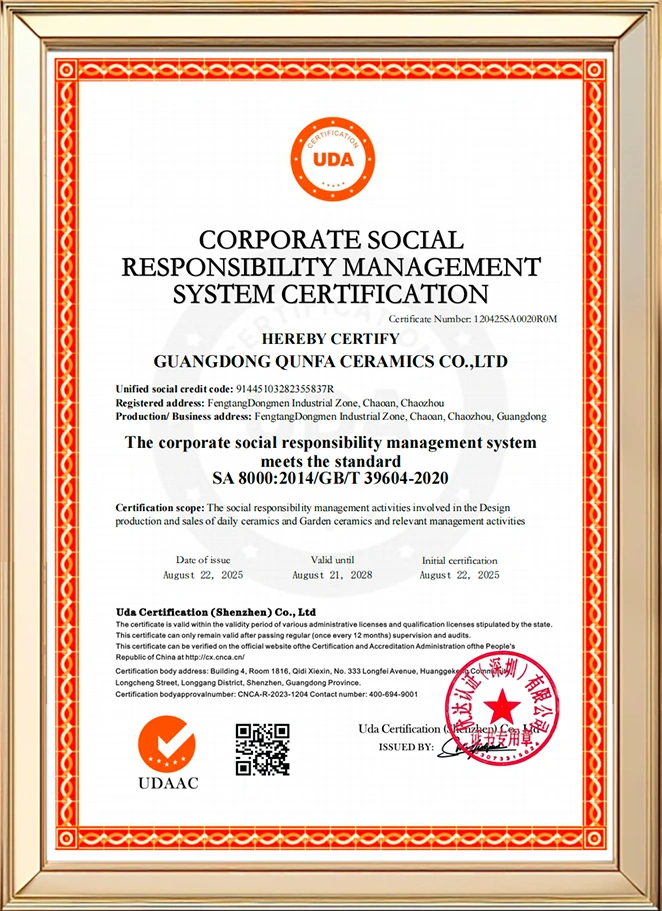

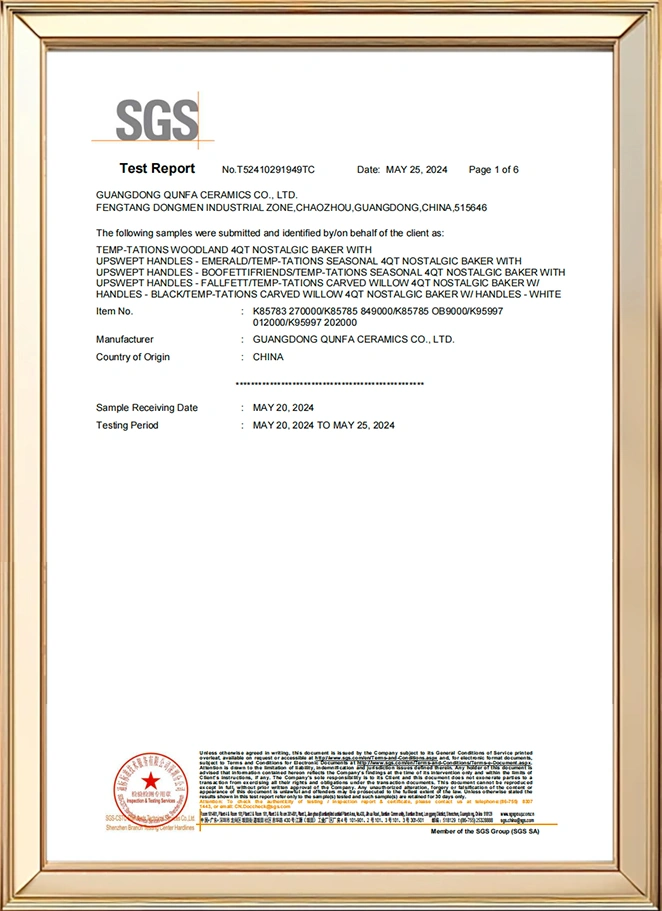

Explore Our Certification

Design Capabilities

Innovative Design Capabilities for Customized Ceramics Manufacturing

Qunfa Ceramics’ design team brings together top designers from home and abroad, dedicated to providing customers with innovative and market-competitive ceramic products. We deeply analyze market needs and combine them with modern trends to create ceramic products that are both aesthetically pleasing and practical. Whether it’s original design or customized development, we can quickly respond to customer needs and provide tailor-made design solutions.

Continuous Innovation and Customer Focus

Get a Quote

FAQ

- Are you a manufacturer or trade company?

We are a professional manufacturer of ceramic bakeware, tableware, pet bowls, garden pots and home decor with 30+ years of experience.

- What is the minimum order quantity?

Our standard MOQ is 1,000 pieces per model, we are open to negotiation based on your specific needs.

- What about the lead time for mass production?

Typically, 55-60 days, depending on order quantity and season.

- What certificates do you have?

We are certified with CIQ, SGS, BV, LFGB, GSV, FCCA, ISO 9001, SMETA 4P, FAD, and more.

- Where is your factory located? How can I visit there?

Our factory is in Chaozhou, Guangdong, China, about 3 hours by high-speed rail from Guangzhou. We warmly welcome all visitors!